Most Popular Products

https://www.whirlercentrifugals.com/post/cassava-modified-starch-industrial-separation-extraction-plant

https://www.whirlercentrifugals.com/post/cassava-modified-starch-industrial-separation-extraction-plant Specification

- Type

- Starch Plant

- Material

- SS304

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 440 Volt (v)

- Power

- 250000 Watt (w)

https://www.whirlercentrifugals.com/post/cassava-modified-starch-industrial-separation-extraction-plant Trade Information

- Minimum Order Quantity

- 1 Number

- Delivery Time

- 4

About https://www.whirlercentrifugals.com/post/cassava-modified-starch-industrial-separation-extraction-plant

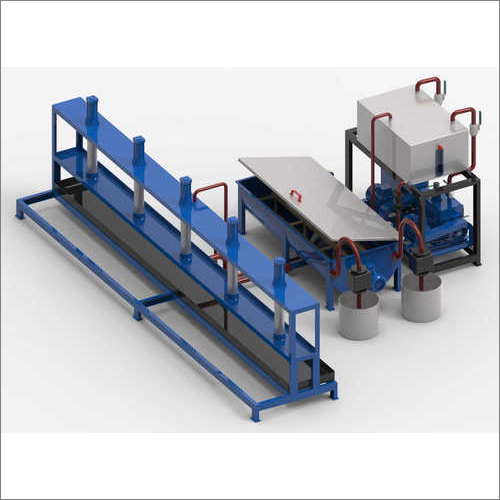

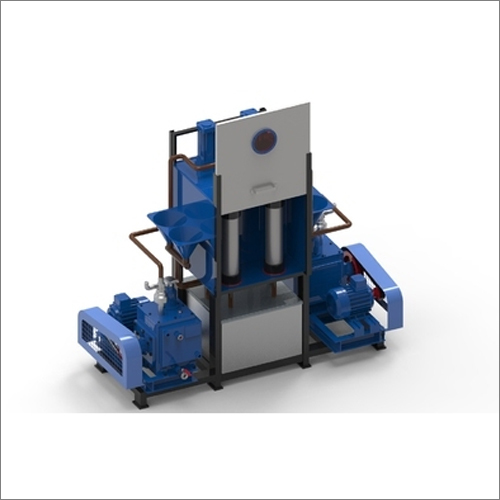

The **Cassava High-Fructose Corn Syrup (HFCS) Automatic Concentration Refining Unit** is a sophisticated, integrated system designed to transform raw starch milk into high-purity sweeteners. This unit is pivotal in modern starch processing, managing the complex transition from glucose to fructose through precise enzymatic isomerization and rigorous purification.

The refining section employs advanced decolorization using activated carbon and multi-stage ion exchange resins to eliminate organic acids, minerals, and pigments, ensuring a crystal-clear, stable final product. Following purification, the automatic concentration phase utilizes energy-efficient multi-effect falling film evaporators. These systems precisely increase the syrup's Brix level while protecting its thermal stability and sensory profile.

Equipped with a state-of-the-art PLC control system, the unit offers real-time monitoring of temperature, flow rates, and concentration levels. This high degree of automation ensures consistent product quality, optimizes steam consumption, and reduces labor requirements, delivering a premium HFCS that meets the stringent standards of the global food and beverage industry.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Starch Plant Category

sago dextrin High Capacity Stabilization Production Unit

Price 5000000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Control System : PLC Control

Automatic Grade : Automatic

potato cross-linked starch High Performance Milling Manufacturing Plant

Price 5000000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Control System : PLC Control

Automatic Grade : Automatic

maize pregelatinized starch Laboratory Packaging Production Plant

Price 5000000.0 INR / Tons

Minimum Order Quantity : 1 Number

Computerized : Yes

Control System : PLC Control

Automatic Grade : Automatic

rice resistant starch Continuous Homogenization Production Unit

Price 5000000.0 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Control System : PLC Control

Automatic Grade : Automatic

|

WHIRLER CENTRIFUGALS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |