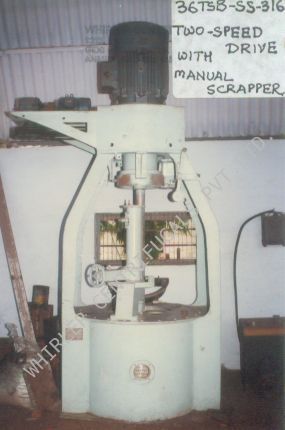

Industrial Centrifuges

Industrial Centrifuges Specification

- Product Type

- Industrial Centrifuge

- Material

- Mild Steel

- Type

- Batch Type

- Centrifugal Chamber

- Stainless Steel Chamber

- Motor

- 3 Phase Electric Motor

- Refrigeration System

- No

- Temperature Control Range

- Ambient to 80C

- Speed

- Up to 3000 RPM

Industrial Centrifuges Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 15 Days

- Packaging Details

- Standard

- Main Domestic Market

- All India

About Industrial Centrifuges

We are a quality-oriented firm, engaged in manufacturing, supplying and exporting a wide range of Industrial Centrifuges. These centrifuges are manufactured by our diligent professionals using premier-grade metallic and non-metallic components. Our firm is backed by diligent quality controllers, who enable us to test the offered centrifuges on different parameters to ensure flawlessness. To suit budgetary constraints of patrons, we offer these centrifuges at reasonable price range. Some special features of the offered Industrial Centrifuges are listed as follows:

- Robust construction

- Low maintenance

- Prolonged functional life

- Easy installation

Robust Construction and High Efficiency

This batch-type centrifuge blends a mild steel exterior with a corrosion-resistant stainless steel chamber, ensuring longevity and cleanliness during continuous operation. The 3-phase electric motor delivers consistent power, allowing for swift and thorough separation processes at up to 3000 RPM. Its suitable for companies seeking long-term, dependable solutions for their material processing requirements.

Versatility in Temperature and Operation

Designed for flexibility, the centrifuge operates efficiently from ambient temperature up to 80C, enabling use with a wide variety of materials and processes. This adaptability makes it an excellent choice for manufacturers in different sectors who require both quality and operational versatility without the complexity of integrated refrigeration.

FAQs of Industrial Centrifuges:

Q: How does an industrial centrifuge without refrigeration maintain temperature control?

A: This centrifuge operates within a temperature range from ambient up to 80C. Although it does not have built-in refrigeration, it can be externally regulated or cooled as needed. The system relies on ambient conditions and process input to manage temperature, making it suitable for applications that do not require sub-ambient cooling.Q: What materials are used in the construction of this centrifuge, and why?

A: The main body is constructed from mild steel for structural strength, while the centrifugal chamber is made of stainless steel. Stainless steel is chosen for its resistance to corrosion and ease of cleaning, ensuring hygiene and durability during repeated industrial use.Q: When should a batch-type centrifuge like this be used in manufacturing processes?

A: A batch-type centrifuge is beneficial for applications that require processing of specific quantities at a time, such as in pharmaceuticals, chemicals, or food industry operations. Use it when consistent, repeatable separation of solids and liquids or clarification processes are essential.Q: Where can clients purchase or source these centrifuges in India?

A: These centrifuges are available from a wide network of Indian dealers, distributors, exporters, fabricators, manufacturers, producers, retailers, suppliers, traders, and wholesalers. This ensures accessibility across major industrial cities and regions in the country.Q: What is the process for using this centrifuge in an industrial setting?

A: The process involves loading the batch material into the stainless steel chamber, setting the required speed (up to 3000 RPM), and, if necessary, managing temperature via external means. Once parameters are set, the centrifuge operates to efficiently separate or clarify the batch, after which the material can be safely unloaded.Q: What are the main benefits of using a non-refrigerated industrial centrifuge with a stainless steel chamber?

A: This centrifuge provides fast and effective separation, easy cleaning, and robust durability, especially important for industries handling sensitive or reactive materials. The absence of refrigeration simplifies maintenance and reduces operational costs for users not requiring cold processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Centrifuge Category

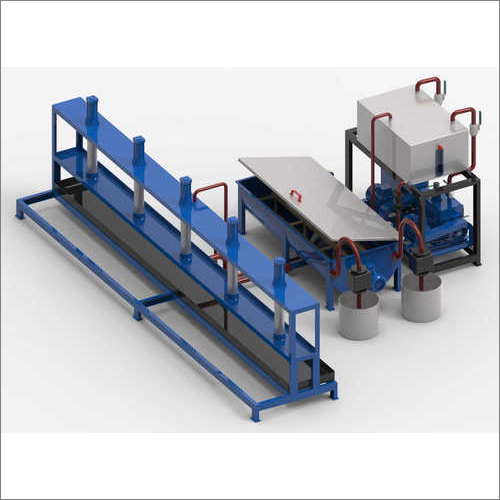

Bottom Discharge Centrifuge

Price 185000 INR / Unit

Minimum Order Quantity : as per product Piece

Material : Stainless Steel (SS304/SS316 as per requirement)

Speed : Up to 1000 RPM (Variable depending on model)

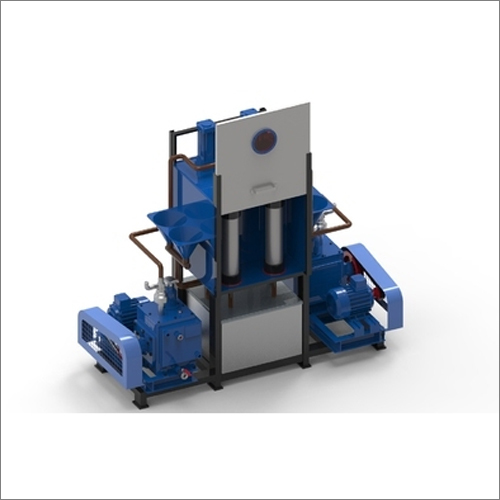

Decanter Type Centrifuge

Price 1450000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Speed : Up to 4000 RPM

Three Point Suspended Centrifuge

Price 200000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1

Speed : 20003000 RPM

Four Point Suspended Centrifuge

Minimum Order Quantity : 1 Unit

Material : SS

Warranty : 1 Year

Centrifugal Compressor : Single Stage

|

WHIRLER CENTRIFUGALS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |