De Watering Decanter

De Watering Decanter Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Asia, Central America, Middle East, Africa, Western Europe

- Main Domestic Market

- All India

About De Watering Decanter

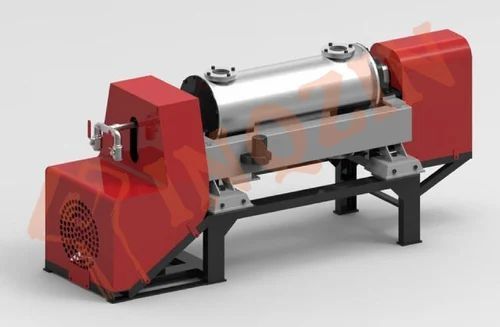

De Watering Decanter

A dewatering decanter, also known as a centrifugal decanter or simply a decanter centrifuge, is a specialized industrial equipment used for separating solids from liquids in various processes. It employs centrifugal force to accelerate the sedimentation process, enabling efficient separation of solids and liquids with differing densities.

The primary components of a dewatering decanter include:

Bowl: This is the main rotating component of the decanter. It consists of a cylindrical drum that spins at high speeds. The mixture of solids and liquids to be separated is fed into the bowl.

Screw Conveyor: Located within the bowl, this helical conveyor rotates at a slightly different speed than the bowl. As the bowl spins, the screw conveyor's rotation pushes the separated solids towards the conical end of the bowl.

Scroll: The conical end of the bowl contains a scroll, which is a specialized helical structure. The scroll rotates at a different speed from both the bowl and the screw conveyor. Its purpose is to convey the separated solids, also known as the cake, to the discharge ports.

Differential Speeds: The key principle behind the dewatering decanter's operation is the use of differential speeds. The bowl, screw conveyor, and scroll all rotate at different speeds, creating a controlled environment for the separation process.

Here's how a dewatering decanter works:

Feeding: The mixture of solids and liquids is introduced into the bowl, typically through a feed pipe at the center. The rotation of the bowl causes the mixture to distribute along the bowl's inner surface.

Separation: Due to the centrifugal force generated by the high-speed rotation, solid particles with higher density than the liquid phase migrate towards the bowl's inner wall, forming a layer of solids against the wall. Meanwhile, the liquid phase forms a clear layer closer to the center of the bowl.

Conveying: The screw conveyor, rotating at a slightly slower speed than the bowl, continuously transports the separated solids, or cake, from the solids layer towards the conical end of the bowl.

Dewatering: As the cake moves along the screw conveyor, excess liquid is expelled through the gaps in the conveyor's helical structure. This dewatering process results in a solid cake with a lower moisture content.

Discharge: The scroll, which rotates at a different speed from both the bowl and the screw conveyor, gradually pushes the dewatered cake towards the discharge ports. The dewatered cake is then collected and removed for further processing or disposal.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Decanter Centrifuges Category

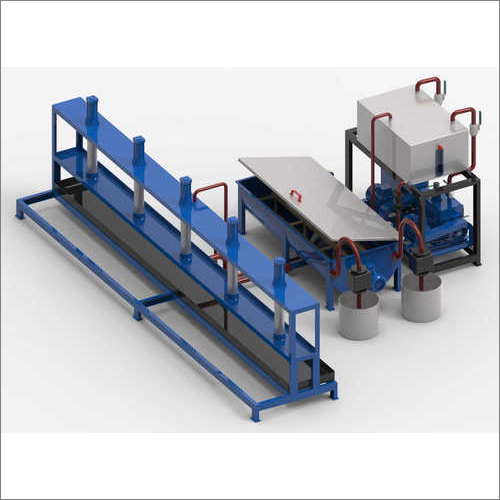

New Effluent SS316 Continuous Drying Decanter Centrifuge Press

Price 800000.0 INR / Unit

Minimum Order Quantity : 1 Number

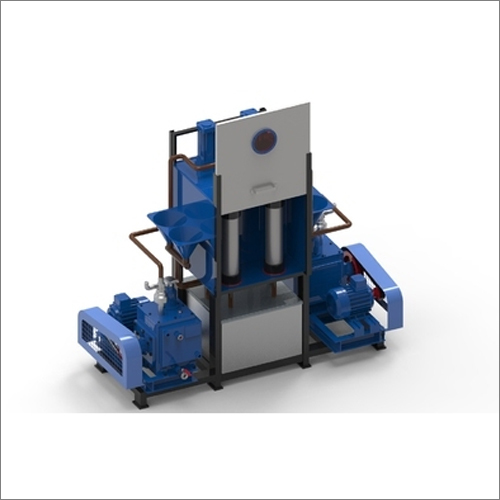

Install ETP Hastelloy Continuous Dehydrating Decanter Belt Press

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Novel STP SS304 Self Cleaning Draining Decanter Centrifuge

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

|

WHIRLER CENTRIFUGALS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |