Decanter Type Centrifuge

Decanter Type Centrifuge Specification

- Product Type

- Decanter Type Centrifuge

- Material

- Stainless Steel

- Type

- Horizontal Decanter

- Centrifugal Chamber

- High Strength Alloy Steel

- Motor

- Heavy Duty Electric Motor

- Refrigeration System

- Not Included

- Temperature Control Range

- Ambient to 100C

- Speed

- Up to 4000 RPM

Decanter Type Centrifuge Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 15 Days

- Packaging Details

- Standard

- Main Domestic Market

- All India

About Decanter Type Centrifuge

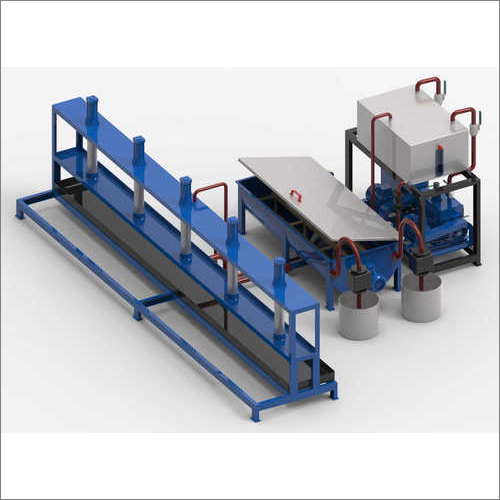

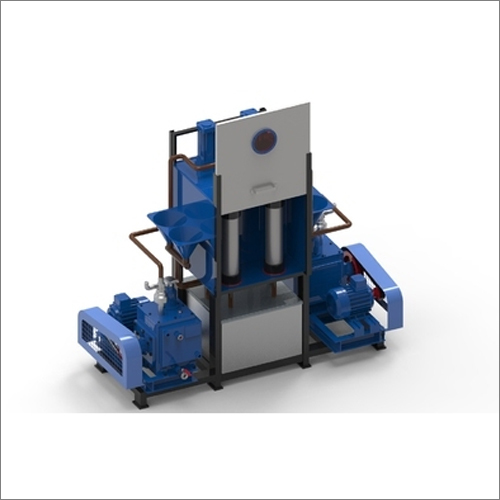

We are reckoned across the globe as an eminent firm, which is engaged in manufacturing, supplying and exporting Decanter Type Centrifuge. It rotates at high speed that generate optimum centrifugal force. With the help of diligent professionals, offered centrifuge is manufactured by our employees using qualitative components. With the assistance of our experienced logistics personnel, we timely deliver this centrifuge at the premises of our clients. We offer this Decanter Type Centrifuge to our clients in different models and specifications to meet their requirements.

Decanter Type Centrifuge:

A Screw Conveyor and Bowl assembly (eccentric) rotates at high speed generating high centrifugals forces (separating effect-values), which accelerate sedimentation / settling. The solids settle near the bowl wall and are conveyed to solids discharge by screw rotating at different speed in bowl.

The screw speed is adjustable and can be changed to achieve specific output like - clearer liquid and/or drier solids. The advantages of Decanter Centrifuges are,

- Easy installation and does not require specific foundation for installation.

- Low maintenance as the precision built centrifuge gives long trouble free operating life.

- Gives continuous uninterrupted high throughput giving high outputs.

- Easily adaptable to variation in feed parameter.

Specification

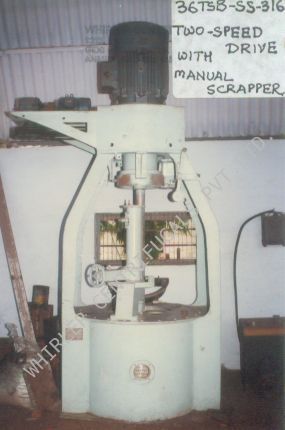

| Product | Centrifuge Repairing |

| Service Provider | Whirler Centrifugals Pvt Ltd |

| Type | Service |

| Type Of Machine | Guniting |

| Type Of Industry | Automobile |

| Location/City | Ghaziabad |

Advanced Centrifugal Separation Technology

The horizontal decanter centrifuge incorporates cutting-edge engineering, combining a stainless steel body with a high-strength alloy steel chamber for reliable and efficient separation. Its heavy-duty electric motor supports sustained operation across industrial environments, making it an excellent choice for businesses prioritizing robust and long-lasting equipment.

Versatile Applications Across Industries

With its ability to process materials at speeds of up to 4000 RPM and tolerate temperatures up to 100C, this centrifuge meets the diverse requirements of sectors including chemical, pharmaceutical, food processing, and wastewater management. Its ambient temperature-based design eliminates the need for refrigeration, simplifying setup and reducing running costs.

FAQs of Decanter Type Centrifuge:

Q: How does a decanter type centrifuge operate without a refrigeration system?

A: This centrifuge is designed to function efficiently at ambient temperatures up to 100C. The heavy-duty electric motor and high-strength materials enable optimal separation performance without relying on external cooling, making operation simpler and maintenance easier.Q: What are the main benefits of using a horizontal decanter centrifuge with stainless steel construction?

A: Stainless steel offers superior corrosion resistance and durability, making the centrifuge ideal for demanding environments. It also ensures hygienic processing, which is especially important in food, pharmaceutical, and chemical industries.Q: When is this decanter centrifuge most effectively used?

A: The centrifuge is most effective for continuous solid-liquid separation processes where temperatures do not fall below ambient or exceed 100C, and where robust, reliable equipment is required for high-speed operation.Q: Where can this decanter type centrifuge be supplied or installed within India?

A: This product is available through a network of dealers, exporters, fabricators, manufacturers, suppliers, traders, retailers, and wholesalers across India, ensuring prompt supply and support anywhere in the country.Q: What processes are typically supported by this centrifuge?

A: Common applications include the separation of solids from liquids in industries such as food processing, chemicals, pharmaceuticals, and environmental waste treatment, where efficient and high-throughput performance is essential.Q: How is the speed of the centrifuge controlled, and what is its operational limit?

A: The centrifuges speed can be adjusted according to process requirements, with a maximum operational speed of up to 4000 RPM. This adjustability allows precise separation tailored to specific material properties.Q: What are the advantages of a heavy-duty electric motor in this centrifuge?

A: A heavy-duty electric motor provides the torque and reliability necessary for continuous, high-speed operation, thus reducing downtime and ensuring consistent process results during demanding separation tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Centrifuge Category

Industrial Centrifuges

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Bottom Discharge Centrifuge

Price 185000 INR / Unit

Minimum Order Quantity : as per product Piece

Material : Stainless Steel (SS304/SS316 as per requirement)

Horizontal Basket Pusher Centrifuge

Minimum Order Quantity : 1 Unit

Material : SS

Warranty : 1 Year

Usage : Industrial

Four Point Suspended Centrifuge

Minimum Order Quantity : 1 Unit

Material : SS

Warranty : 1 Year

Usage : Industrial

Centrifugal Compressor : Single Stage

|

WHIRLER CENTRIFUGALS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |