Front Loading Industrial Washing Machine

Front Loading Industrial Washing Machine Specification

- Drum Diameter

- 800 mm

- Drum Capacity

- 240 Liters

- Heating

- Electric or steam heating options

- Control System

- Microprocessor controlled, programmable touch screen interface

- Cleaning Method

- Automatic, front loading with high spin extraction

Front Loading Industrial Washing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 15 Days

- Packaging Details

- Standard

- Main Domestic Market

- All India

About Front Loading Industrial Washing Machine

Whirler make Front Loading Washing Machine

Whirler, Industrial Washing Machine Front-loading type, open pocket.

No water spillage, absolutely dry floor.

Complete Stainless Steel (SS 304) inner & outer drum, front door

Long lasting rust free operation.

Automatic features like auto timed, auto reverse, auto temperature control etc.

Ideally suited for Laundry Wash & Stone Wash.

| Capacity | 15 kg | 30 kg | 60 kg | 100 kg |

| Cylinder size in mm | Dia -750 x 450 | Dia 900 x 500 | Dia 1150 x 620 | Dia 1450 x 725 |

| Cylinder volume | 200 ltr | 375 ltr | 650 ltr | 1200 ltr |

| Door opening | Dia-400 mm | Dia-400 mm | Dia 400 mm | Dia 500 mm |

| Water inlet size | 1 | 1.5 | 1.5 | 2 |

| Steam requirement | 7.5 kg / hour | 15 kg / hour | 30 kg / hour | 50 kg / hour |

| Electrical requirement | 5 kw | 6 kw | 9 kw | 12 kw |

| Motor | 1 hp | 2 hp | 3 hp | 5 hp |

| Drain size | 1 | 2 | 3 | 4 |

| Overall dimensions in mm (l x b x h) | 1050 x 1100 x 1550 | 1220 x 1250 x 1730 | 1570 x 2014 x 1850 | 1490 x 2250 x 2000 |

| Net weight | 500 kg | 450 kg | 610 kg | 950 kg |

Advanced Control and Efficiency

Equipped with a sophisticated microprocessor control system and a programmable touch screen, this washer offers superior flexibility and consistency. Easily customize wash cycles to suit various textiles, while automated functions reduce operator intervention. The state-of-the-art design is ideal for demanding industrial environments where uptime and precision are essential.

Spacious Drum and Superior Extraction

With an 800 mm diameter drum and 240-liter capacity, the machine handles large batches efficiently, saving time and labor costs. The front-loading design facilitates easy loading and unloading, while high spin extraction ensures quick drying and energy savings. Whether cleaning linens or heavy-duty fabrics, consistency is guaranteed every cycle.

FAQs of Front Loading Industrial Washing Machine:

Q: How does the microprocessor-controlled touch screen interface enhance machine operation?

A: The touch screen interface allows users to program and monitor wash cycles with precision. The microprocessor ensures each cycle is performed accurately, reducing human error and enabling customized settings for different fabric types, maximizing cleaning efficiency and fabric care.Q: What heating options are available for the machine, and how do I choose between them?

A: This industrial washer provides electric and steam heating options. Choose electric heating for easier installation and lower upfront cost or select steam heating for integration with central boiler systems, suited for larger operations with high throughput.Q: When should a business consider using this industrial washing machine?

A: Businesses should consider this machine when they have high-volume laundry needs, such as in hotels, hospitals, or garment industries. Its large capacity and automation make it ideal for scenarios demanding consistent, bulk cleaning with minimal manual intervention.Q: Where can the Front Loading Industrial Washing Machine be installed?

A: It is suitable for installation in commercial laundry rooms, factories, hotels, hospitals, and large institutions. Ensure the location has suitable power and plumbing for either electric or steam heating as required.Q: What is the process for operating the washing machine?

A: Load the laundry through the front door, select or customize the desired wash program using the touch screen, and start the cycle. The machine manages water levels, temperature, and spin cycles automatically, with status updates available on the display.Q: How does high spin extraction benefit laundry operations?

A: High spin extraction removes more moisture from fabrics during the final cycle, reducing drying time and energy costs. This leads to faster turnaround and improved operational efficiency, especially valuable in commercial settings.Q: What advantages does dealing with a manufacturer, supplier, or distributor in India offer?

A: Working with local partners ensures reliable after-sales service, customized support, and timely delivery. As a reputable manufacturer and supplier in India, we provide comprehensive assistance from installation to maintenance, catering to diverse business needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laundry Equipment Category

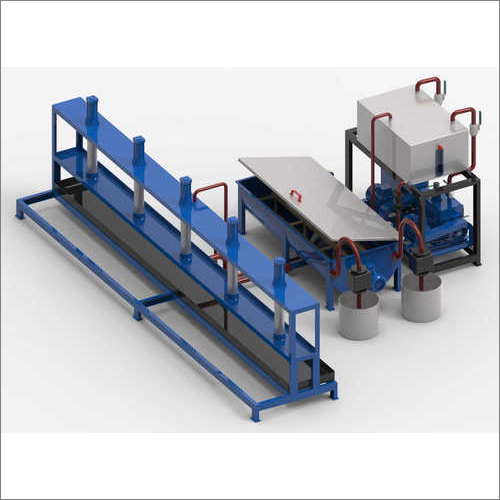

Flat Work Ironer

Minimum Order Quantity : 1 Unit

Color : Sliver

Material : Stainless Steel

Usage : Industrial

Size : 2260 x 1346 x2133 mm

Washing Machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Sliver

Material : Stainless Steel

Usage : Industrial

Size : Standard

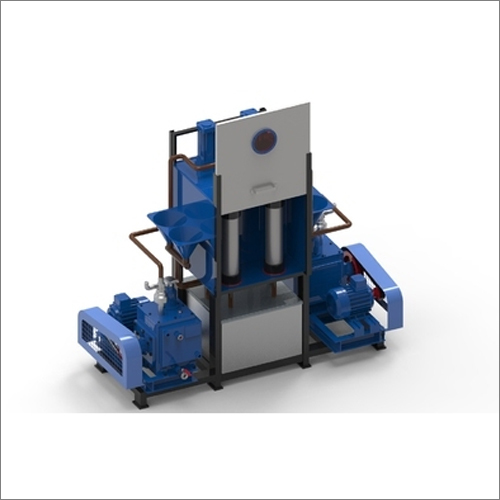

MTO Dry Cleaning Machines

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : White

Material : SS

Usage : Industrial

Size : 1000 x 1025 x 1400mm

Steam Boilers

Minimum Order Quantity : 1 Unit

Color : White Blue

Material : Stainless Steel

Usage : Industrial

Size : 450 x 450 x 625 mm

|

WHIRLER CENTRIFUGALS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |