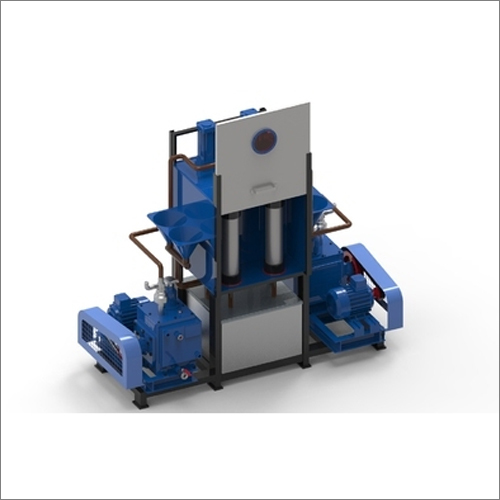

Bottom Discharge Centrifuge

Bottom Discharge Centrifuge Specification

- Product Type

- Bottom Discharge Centrifuge

- Material

- Stainless Steel (SS304/SS316 as per requirement)

- Type

- Industrial Centrifuge

- Centrifugal Chamber

- Polished Stainless Steel, Corrosion Resistant

- Refrigeration System

- Not Available

- Temperature Control Range

- Ambient to Specific depending on customization

- Speed

- Up to 1000 RPM (Variable depending on model)

Bottom Discharge Centrifuge Trade Information

- Payment Terms

- Cheque

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 15 Days

- Packaging Details

- Standard

- Main Domestic Market

- All India

About Bottom Discharge Centrifuge

Established with goal to attain optimum patron-satisfaction, our firm is involved in manufacturing, supplying and exporting Bottom Discharge Centrifuge. Qualitative stainless steel and mild steel is used by our employees for manufacturing the offered centrifuge. Clients can obtain this centrifuge from our firm at affordable prices. It is widely used in sugar mills for solid-liquid separation for Dextrose Mono Hydrate (DMA) and Dextrose Anhydrus(DA). We conduct numerous quality tests on this Bottom Discharge Centrifuge to remove its flaws.

Precision Engineering for Industrial Applications

Our centrifuge is designed for a range of industries requiring robust separation capabilities. The polished stainless steel chamber ensures minimal contamination and enhanced durability. Customizable material options (SS304/SS316) and variable speed up to 1000 RPM provide flexibility for diverse processing needs.

Customizable Performance and Enhanced Corrosion Resistance

The centrifuge provides temperature control from ambient to specific, as required for your application. Its corrosion-resistant features make it particularly suitable for challenging industrial environments, ensuring long-term reliability and consistent results in operations.

FAQs of Bottom Discharge Centrifuge:

Q: How is the temperature controlled in the Bottom Discharge Centrifuge?

A: Temperature control in the Bottom Discharge Centrifuge can be customized according to user requirements, starting from ambient levels. While refrigeration systems are not available, the centrifuge offers flexible control to meet specific operational needs.Q: What are the material options for the centrifugal chamber?

A: The centrifugal chamber is made from high-quality polished stainless steel, with options for SS304 or SS316 based on your corrosion resistance requirements and application demands.Q: When should I choose a variable speed centrifuge for my facility?

A: A variable speed centrifuge is ideal when processing loads with differing separation requirements. Our model operates up to 1000 RPM, allowing users to optimize speed for efficiency and safety based on the material being processed.Q: Where can the Bottom Discharge Centrifuge be sourced in India?

A: This centrifuge is available across India through various dealers, distributors, exporters, manufacturers, suppliers, traders, and wholesalers, ensuring easy access for your industrial needs.Q: What is the process for customizing the centrifuge to my requirements?

A: Customization involves selecting the suitable material (SS304/SS316), specifying the speed range, and defining the temperature control range. Contact your supplier or manufacturer to discuss process specifications and receive tailored solutions.Q: How is the Bottom Discharge Centrifuge typically used in industrial settings?

A: It is utilized for solid-liquid separation, clarification, and product recovery in chemical, pharmaceutical, and food industries. Its robust build and customizable settings make it versatile for various industrial separation processes.Q: What are the main benefits of using a Bottom Discharge Centrifuge with polished stainless steel chambers?

A: Key benefits include corrosion resistance, easy cleaning, minimized contamination, and enhanced durability, supporting efficient and reliable operation in high-demand industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Centrifuge Category

Industrial Centrifuges

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Speed : Up to 3000 RPM

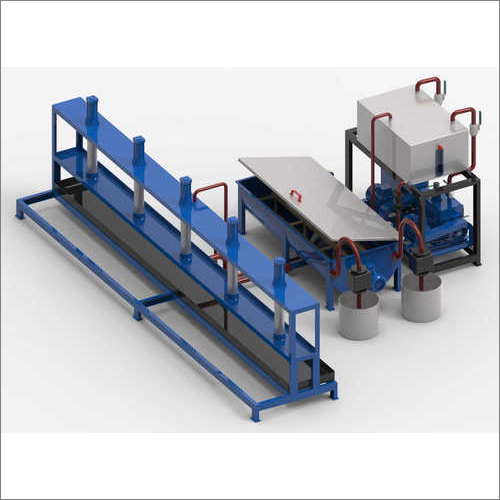

Horizontal Basket Pusher Centrifuge

Minimum Order Quantity : 1 Unit

Material : SS

Warranty : 1 Year

Usage : Industrial

Speed : 1440 RPM

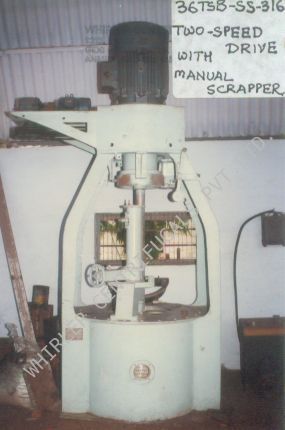

Three Point Suspended Centrifuge

Price 200000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1

Speed : 20003000 RPM

Four Point Suspended Centrifuge

Minimum Order Quantity : 1 Unit

Material : SS

Warranty : 1 Year

Usage : Industrial

|

WHIRLER CENTRIFUGALS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |